Cason Pig Feed Trough Suppliers

- Model

- Stainless Steel Feed Trough

Review

Description

Cason is a company that specialized in developing and selling pig breeding equipment and environmental protection equipment, providing pig breeding equipment for many large farms in China. our products are exported to the United States, Australia, Russia, Korea, Malaysia, and other countries.

Cason Feeding System

Pig farming equipment is an indispensable product for modern pig farms, which can ensure a free diet and drinking water for pigs.

While meeting the daily food and water needs of pigs, it can also save feed and water and reduce the cost of raising pigs.

Different types of troughs are needed for different growth stages of pigs.

Cason is a famous pig trough supplier in China, we have feeding trough for sows, single feed trough, round hog feeders, nursery pig feeders, finishing pig trough, a supplementary feeding trough for piglets, and common trough, we can also provide customized service for our customers.

Cason is a famous pig trough supplier in China, we have feeding trough for sows, single feed trough, round hog feeders, nursery pig feeders, finishing pig trough, a supplementary feeding trough for piglets, and common trough, we can also provide customized service for our customers.

Feeding Trough For Sow

Each sow trough is made of thickened 304 stainless steel, which is corrosion-resistant and long-lasting.

The wrapped edge design avoids scratching the sow and prevents the sow from chewing the trough.

The surface of the pig trough is smooth and the raised front-end design effectively prevents feed overflow and saves feed.

The side stainless steel stamping process strengthens the side plate and provides better stability.

The wrapped edge design avoids scratching the sow and prevents the sow from chewing the trough.

The surface of the pig trough is smooth and the raised front-end design effectively prevents feed overflow and saves feed.

The side stainless steel stamping process strengthens the side plate and provides better stability.

Product function: Automatic feed delivery to sows, with free feeder, gestation crate, and farrowing bed. A feeding trough for sow can be turned freely, and a convenient cleaning tank.

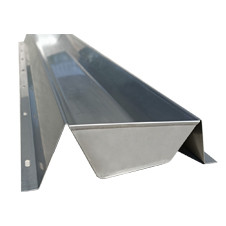

Stainless Steel Single Feed Trough

Stainless steel single feed trough is made of 304 stainless steel, the length style can be customized, and the plate thickness is 1.2mm.

The single feed trough is low on the side close to the pig, which is convenient for the pig to feed. The side of the trough away from the pigs is high to reduce the spilling of feed.

The edge of the trough is designed with long round holes, which are convenient to fix on the ground.

Stainless steel single-feed trough from cason is suitable for dry feed and liquid feed.

The single feed trough is low on the side close to the pig, which is convenient for the pig to feed. The side of the trough away from the pigs is high to reduce the spilling of feed.

The edge of the trough is designed with long round holes, which are convenient to fix on the ground.

Stainless steel single-feed trough from cason is suitable for dry feed and liquid feed.

Round Hog Feeder

Round hog feeder for pigs is the newest breeding equipment integrating automatic trough and drinking water function, which is also the latest patented technology product of cason.

Both powder feed and pellet feed can be conveyed and evenly discharged through the valve.

It can meet the demand for water and feed for different stages of pigs, enhance the feed conversion rate, and improve the speed of growing meat.

Round feeder trough for pigs consists of a material drum and a tube combined together. The bottom of the bucket is connected to the plastic pendulum, and there is a central rod inside the bucket, which is fixed to the feed tube. The amount of feed can be controlled by adjusting the device to raise and lower the central rod.

Both powder feed and pellet feed can be conveyed and evenly discharged through the valve.

It can meet the demand for water and feed for different stages of pigs, enhance the feed conversion rate, and improve the speed of growing meat.

Round feeder trough for pigs consists of a material drum and a tube combined together. The bottom of the bucket is connected to the plastic pendulum, and there is a central rod inside the bucket, which is fixed to the feed tube. The amount of feed can be controlled by adjusting the device to raise and lower the central rod.

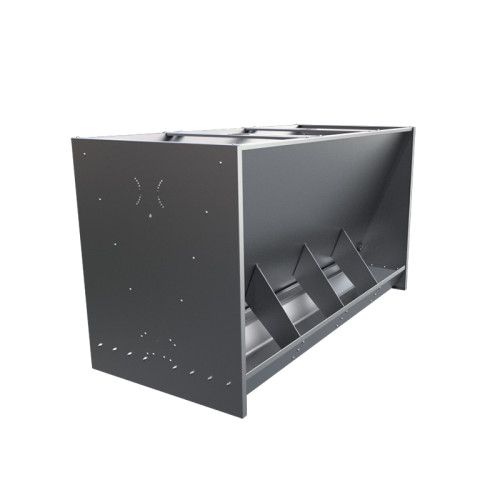

Double-Sided Feeding Trough

The double-sided feeding trough is made of 304 stainless steel, which is not easily deformed.

There is a manual adjustment switch on the side of the trough to adjust the feeding speed.

Large partitions in the feeding area prevent pigs from fighting while eating.

The floor of the trough is designed with R-angle, and the surface is smooth, so it is not easy to accumulate feed.

Both sides of the double fabric tank provide feed for the pigs.

There is a manual adjustment switch on the side of the trough to adjust the feeding speed.

Large partitions in the feeding area prevent pigs from fighting while eating.

The floor of the trough is designed with R-angle, and the surface is smooth, so it is not easy to accumulate feed.

Both sides of the double fabric tank provide feed for the pigs.

Single-Sided Feeding Trough

The difference between a single trough and a double trough is that only one side of the trough provides feed and the other side is near the wall of the barn. The single trough is usually placed on the wall of the barn.

Nursery Pig Feeders

The nursery trough is a classification of single and double-sided troughs, which is a pig trough specially designed and developed by cason for nursery pigs.

Finishing Pig Trough

Fertilizer troughs and single and double-sided troughs have the same function, but slightly different structures, which is a trough developed and sold by cason especially for fattening pigs.

Feeding Trough For Piglet

The use of piglet feeding trough is generally divided into three periods, which are the period of identifying feed, the small amount of feeding, and the period of normal feeding.

Identify The Period of Feed

Start adding a small amount of feed to the trough around 10 days after the piglets are born, so that the piglets can gradually get familiar with the taste.

At this stage, the piglets have very little to eat, so we need to let the piglets get familiar with the taste of the feed first, which becomes the key to the success of the piglet trough.

At this stage, the piglets have very little to eat, so we need to let the piglets get familiar with the taste of the feed first, which becomes the key to the success of the piglet trough.

The Small Amount of Feeding

At this stage, piglets are already feeding in small amounts, so they need to be supplemented with feed several times a day at regular intervals.

When replenishing feed, you must clean up the leftover feed.

When the sow is feeding, the piglet trough should be replenished with feed, which is more beneficial to the piglet's feeding.

When replenishing feed, you must clean up the leftover feed.

When the sow is feeding, the piglet trough should be replenished with feed, which is more beneficial to the piglet's feeding.

The Period of Normal Feeding

3-5 days before the piglets are weaned, the amount of milk from the sow is already difficult to fully meet the nutritional needs of the piglets.

The piglets in this period are also gradually familiar with the taste of feed, and each piglet can take 15-20g per day, still need to use the method of small amounts and multiple times, generally 6-8 times per day, each time to eat within 1-2 hours is appropriate, pay attention to prepare a separate water dispenser for piglets.

The piglets in this period are also gradually familiar with the taste of feed, and each piglet can take 15-20g per day, still need to use the method of small amounts and multiple times, generally 6-8 times per day, each time to eat within 1-2 hours is appropriate, pay attention to prepare a separate water dispenser for piglets.

Q: What is the delivery time of your factory?

A: Generally 5-10 days for series products, and 15-30 days for bulk products and customized products depending on the situation.

Q: How do you guarantee the quality of your products?

A: Generally speaking, as a global pig equipment supplier, we have advanced production facilities. Skilled workers and strict quality ensure that each product meets market requirements.

Q: How does your after-sales service work if the product is damaged?

A: During the 1 year warranty period, our general after-sales service is to replace the damaged part for the customer, but if the damage can be repaired at a minor cost, we will wait for the customer to pay for the repair and refund the cost of the part. (Note: Perishable parts are not included.)

Q: How do we believe in your commitment?

A: If you want to visit our factory, we provide a free shuttle bus from Qingdao airport to our company, you are welcome to visit us.

Q: What advantages do we have?

A: Rich experience: We have more than 10 years of experience in this industry. That means, we can preview the problems for the orders and products. Therefore, it will make sure to reduce the risk of bad situations happening.

Point-to-point service: There is one sale that will serve you from inquiries to products shipped out. During the process, you just need to discuss with her all your problems and that way saves much time.

Free design: If you are not ready for the designs, professional designers will be able to help you with them freely.

Strict QC: For each order, strict inspection will be carried out by the QC department before shipping. The bad quality will be avoided within the door.

Shipping: We have a shipping department and forwarder, so we can promise faster delivery and make the goods well protected.

Point-to-point service: There is one sale that will serve you from inquiries to products shipped out. During the process, you just need to discuss with her all your problems and that way saves much time.

Free design: If you are not ready for the designs, professional designers will be able to help you with them freely.

Strict QC: For each order, strict inspection will be carried out by the QC department before shipping. The bad quality will be avoided within the door.

Shipping: We have a shipping department and forwarder, so we can promise faster delivery and make the goods well protected.