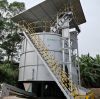

Advantages of harmless treatment equipment

The harmless treatment equipment is a mechanical equipment that uses high temperature to clean sick animals or diseased parts. After humidification and mechanical treatment, it can be boiled into industrial oil, and other residues can also be made into animal feed. Working principle of harmless treatment equipment: using high-pressure saturated steam to directly contact animal tissue.

Mar 23,2023