Cason | Harmless Treatment System Machine | Bio-safety disposal System Machine Manufacturers

Review

Description

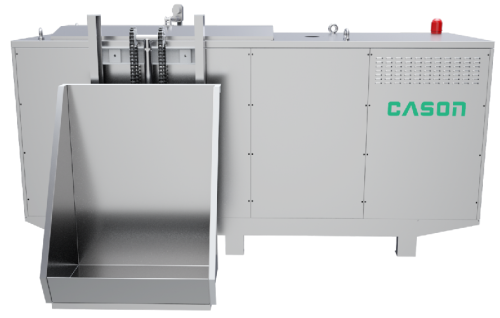

CASON® harmless fermentation machine, the collection of the country's leading bioengineering technology, the world's advanced fermentation equipment technology, and learn from each other in practice, through long-term research and experimental innovation developed. The mixed heating uniformity of the harmless fermentation machine has reached the advanced level in the world. CASON® harmless fermentation machine is a new energy-saving and highly efficient advanced fermentation system which brings together the advantages of both home and abroad. CASON® harmless fermentation machine is widely used in biological fermentation engineering of organic waste resource regeneration. After the user's practice, CASON® harmless fermentation machine has been well received by users at home and abroad.

Product Description

The following is the introduction of high quality CASON® harmless fermentation machine, hoping to help you better understand CASON® harmless fermentation machine. Welcome new and old customers to continue to cooperate with us to create a better future!

CASON® harmless fermentation machine is a new, efficient and energy-saving fermentation system with large coefficient, fast speed and low energy consumption. Safe, dust-free, good sealing performance, easy operation, installation and maintenance, no waste, zero emissions and other advantages. CASON® harmless fermentation machine has scientific and technological advantages in fermentation, sterilization, deodorization, insecticide, degradation of hormones and heavy metals, etc. Wide adaptability to mixed fermentation, no dead Angle, no deposition, with uniform heating, high mixing accuracy. CASON® harmless fermentation machine can choose heat conduction oil, steam, hot water and other heating methods, supporting the spray exhaust exhaust air purification and dust removal system. CASON® harmless fermentation machine company follows the enterprise purpose: quality first, user first, reputation first principle.

1.Product Introduction

CASON® harmless fermentation machine company follows the enterprise purpose: quality first, user first, reputation first principle.

is to put the dead animal carcass into the fermentation bin, after crushing, stirring, heating, drying and microbial high temperature fermentation, to achieve pollution-free, harmless, lightweight and reasonable use of resources.

2.Harmless Fermentation Machine Parameter (Specification)

Item | QWF-70 | QWF-100 | QWF-200 | ||

|---|---|---|---|---|---|

The device volume | 2.2 m³ | 2.6 m³ | 5.1 m³ | ||

Effective volume | 1.8 m³ | 2.2 m³ | 4.5 m³ | ||

Equipment weight (approx.) | 2.2 ton | 3 ton | 4.5 ton | ||

Processing capacity (excluding excipients) | 0.7 ton | 1 ton | 2 ton | ||

Fermentation temperature of materials (℃) | ≥60℃ | ≥60℃ | ≥60℃ | ||

Maximum heating temperature (℃) | 180℃ | 180℃ | 180℃ | ||

After treatment, pathogenic bacteria of swine fever, blue ear disease, foot and mouth disease, ring, pseudorabies and diarrhea were found in the solid substance | NO | NO | NO | ||

Host size (mm) | L*W*H | L*W*H | L*W*H | ||

3490*1200*1880mm | 3800*1500*1880mm | 4650*1700*2100mm | |||

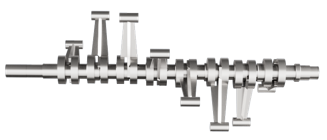

Mixing way | Leaf blade stirring | Leaf blade stirring | Leaf blade stirring | ||

Electric heating power | 24kw | 30kw | 54kw | ||

The drive motor | 5.5kw | 5.5kw | 7.5kw | ||

Heat conduction oil | 230# | ||||

Amount of heat conducting medium | 170L | 170L | 200L | ||

Air purification system | Deodorant purifier | PL500 | PL500 | PL500 | |

Induced draft fan | 0.75KW | 1.5KW | |||

Circulating pump | 0.75kw | ||||

Hydraulic station | 1.5KW | 2.2KW | |||

Feeding way | Hopper lift type | ||||

Control system | PLC + Display + Internet of things | ||||

3.Components of harmless fermentation machine

The CASON® harmless fermentation machine consists of the main fermentation equipment, heating system, gas supply system (optional), exhaust and air purification system, feed/discharge system (optional, according to the user's contract intention) and control system, etc. :

1) Transmission part: the movement of the motor is adjusted to a reasonable speed through the hard-tooth surface gear reducer, and then transferred to the stirring shaft, so that the spindle drives the stirring arm to rotate and flip.

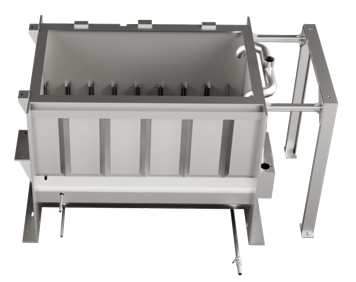

2) Cylinder body: The cylinder body is U-shaped structure with heating jacket.

3) Shell cover part: the shell cover is provided with a number of holes for feeding port, observation port and exhaust port respectively.

4) Discharge port: The discharge port is on the side of the cylinder body for material discharge. It can be broken up in the form of dynamic and electric.

5) Liquid culture spray system (optional) : In order to meet the technological requirements, the biological fermentation needs to spray the gonococcus in the process of material treatment. The spray part is fixed on the end cover, and the liquid is supplied to the spray gun by the feed pump.

6) Air purifier: ammonia gas, hydrogen sulfide and water vapor produced in the initial stage of fermentation are connected with a closed air duct by the induced draft fan and discharged after treatment by the air purifier.

7) Control system: it can automatically realize the whole process from start to stop according to the set program to ensure the normal operation of the fermentation machine. Users can also use manual control.

4.Product Qualification