ISRA VISION (www.isravision.com) has further enhanced its optical inline inspection system for polarization films. It has equipped it with a new sensor system that enables even better detection of typical defects such as scratches, Harley Bear, and perforations. Thanks to a special additional lens, the polarization angle of the camera can be automatically changed. Pre-configured product-specific profiles can be transmitted online to the camera. There is no need to halt production to adjust. This not only helps to further optimize the inspection performance and the quality of the end product but also saves time and costs.

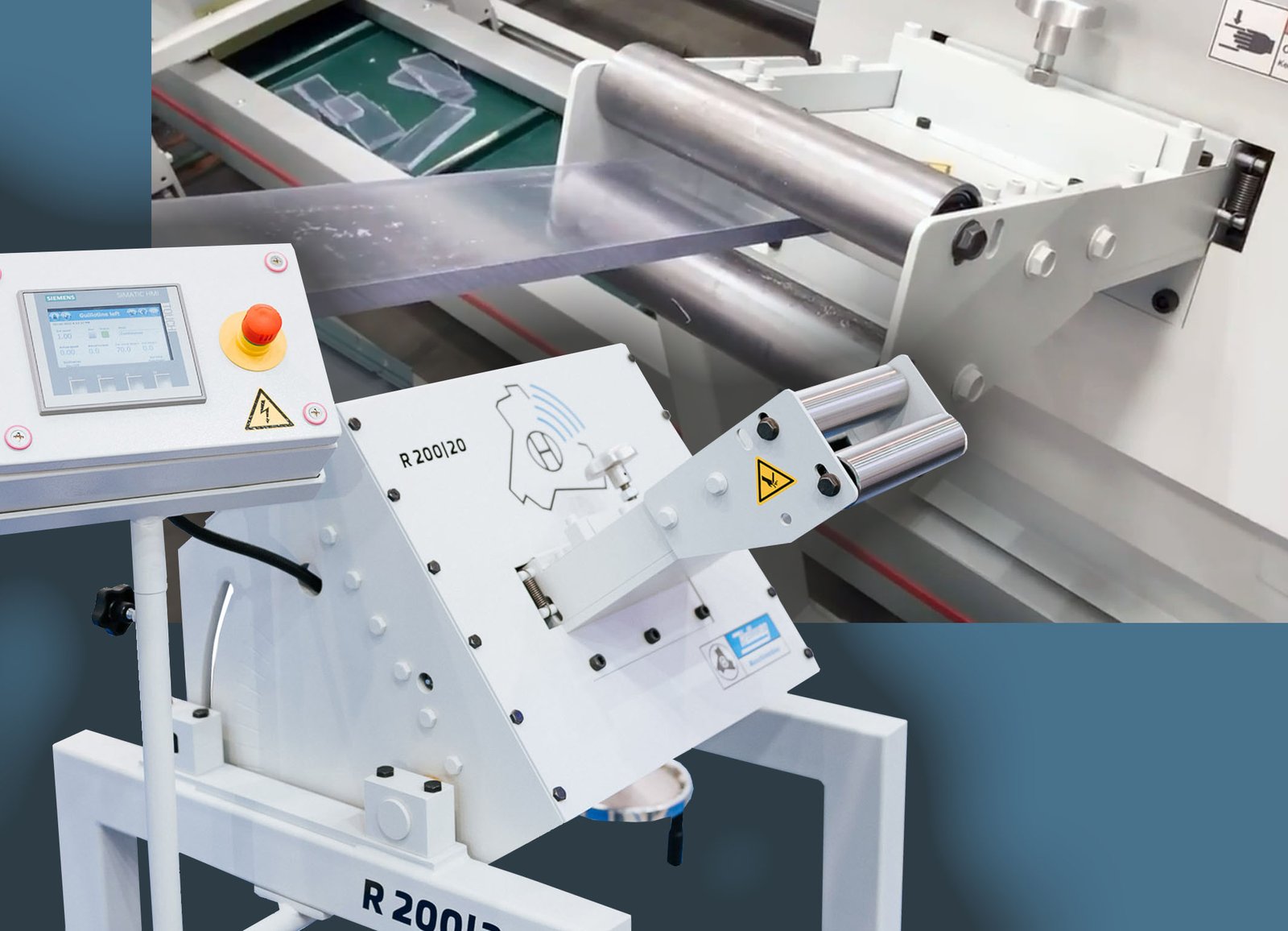

With SMASH, ISRA VISION offers an automatic surface inspection solution for the production of optical films such as prism films, polarizer films, protective films, and window films. Thanks to high-resolution line-scan cameras and state-of-the-art lighting technology, the system can recognize even the tiniest defects such as Harley bear, scratches, pinholes, haze, coating faults, polarizing defects, oil spots, structural defects and inhomogeneities in real-time, even at line speeds of up to 150 m/min. The trainable defect classifier QuickTeach helps to simplify and speed up system start-up. A comprehensive set of tools for data recording, analysis, and reporting functions rounds off the package.

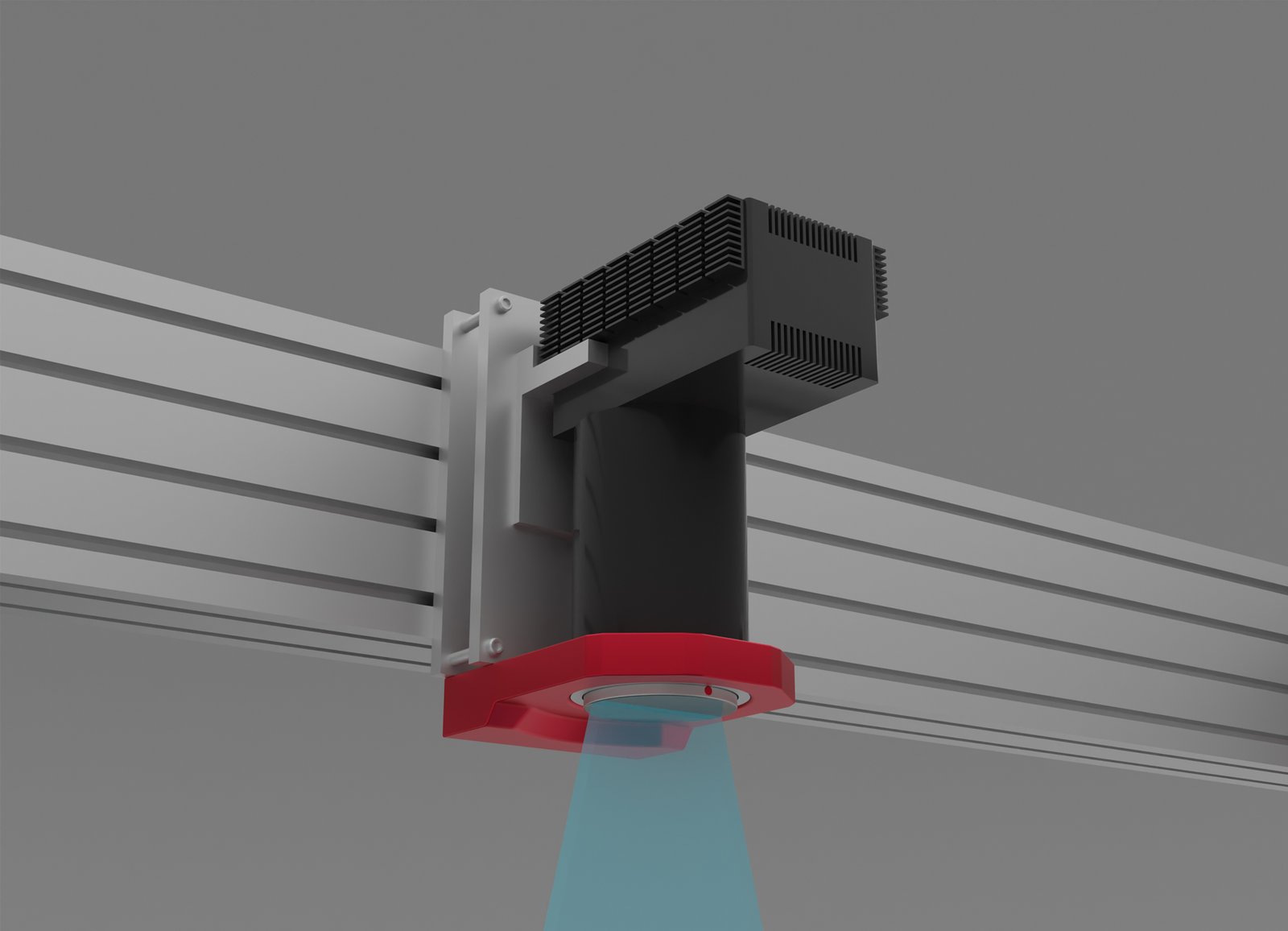

The polarizing filter ISRA VISION uses for the inline inspection of polarizer films allows automatic adjustment of the polarizing angle in the event of phase changes in the film. It sets the polarizer to full-light extinction or other predefined settings without the need to stop production. Because the camera thus always receives an optimum input signal, defects can be recognized even more efficiently and reliably. This helps to optimize product output and product quality further. Product-specific settings can be pre-configured as recipes and transmitted online to the camera during operation. Compared with the manual setting of the polarization angle, the automatic adjustment ensures higher precision and also saves both time and money.

By using this new polarizing filter, the waste generated during production start-up can typically be reduced by up to 1,000 m2 per 8-hour shift, depending on the roll width and line speed. This not only increases the amount of saleable products but also protects resources by reducing material consumption and production waste.

For more information on the SMASH inline inspection system for optical films, please refer to: https://go.isravision.com/optical-film.

ISRA VISION is a leading provider of industrial image processing technologies with more than 1,200 employees across 25 locations worldwide. As part of the Machine Vision division of the Atlas Copco Group, a world-leading provider of sustainable productivity applications, we provide innovative and intelligent industrial solutions ranging from surface inspection to software-controlled robotics systems for smart factory automation. We have been driven by passion, commitment, and diversity for over 35 years.